Condition of Assignment : Load Line Survey

.cap load line .coa loadline .lls .fba .lla .freeboard assignment

Conditions of Assignment of Freeboard

These are the conditions which must be met before free board is assigned to a ship and load line certificate is issued after a load line survey. Free boards are computed assuming ship to be a completely enclosed and water tight / weather tight. But The convention recognizes the practical need for opening in the ship and prescribes means of protection and closure of such openings. These are called condition of assignment

These conditions are given in Load line convention annex 1 chapter 2 which is condition of assignment of freeboard.

Under chapter 2 regulation 10 to 26 describes the conditions of freeboard assignment

REG 10 – INFORMATION TO BE SUPPLIED TO MASTER

1. Ship masters need essential information for loading and ballasting their ships.

2. They are provided with:

→Trim & intact stability booklet

→Damage stability booklet

→ Ballast piping schematic

→ Loading computer (in some cases)

3. Before a new ship is delivered, it must undergo an inclining experiment. The purpose of this experiment is to confirm the ship’s center of gravity.

REG 11 – SUPERSTRUCTURE END BULKHEADS

→ Bulkheads at the exposed end of superstructure need to be of acceptable strength.

REG 12 – DOORS

Superstructure Bulkhead Openings

- Access openings in superstructure bulkheads must have:

- Steel doors

- Permanent attachment

- Door requirements:

- Strength equal to the unopened bulkhead

- Weathertight when closed

- Permanent securing mechanism

- Gaskets and clamping devices

- Operable from both sides

- Open outwards for better protection against sea impact

- To have Sills (raised bracket like structure) with 380mm height

REG 13 – POSITION OF HATCHWAYS, DOORWAYS AND VENTS

.pos .position 1 .position

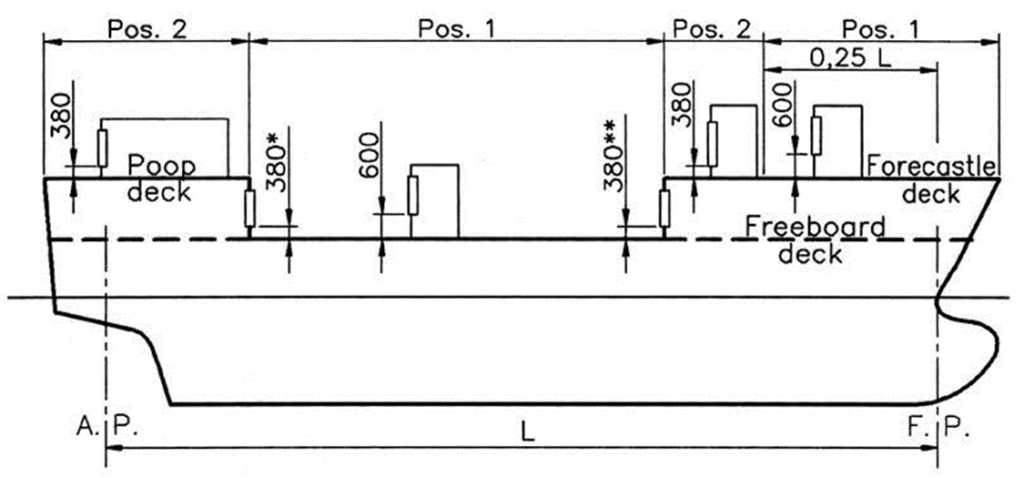

Position 1 (more exposed to seawater)–

→ The freeboard deck,

→ The raised quarter deck

→ The exposed superstructure deck, but only for the front quarter of the ship’s length (0.25L) (measured from FWD perpendicular)

Position 2 (less exposed to seawater)–

→ deck outside position 1

→ & superstructure deck located in position 1 at a deck height above 2nd tier (2nd deck) of superstructure deck.

REG 14 – CARGO & OTHER HATCHWAYS COAMINGS

Construction & securing for cargo hatchway weather-tightness need to comply with the Administration requirements.

Coaming shall be strongly constructed and with minimum height of 600mm when located in

position 1, and 450mm when located in position 2.

REG 15 – HATCHWAY CLOSED BY PORTABLE COVER AND SECURED WEATHERTIGHT

Cover should be made of steel,

Securing for hatchway to be provided in order to efficiently and independently secure each section of the covers.

REG 16 – HATCHWAYS CLOSED BY COVERS

All hatchways shall be fitted with steel cover.

The cover should be weathertight and fitted with gasket and damping devices.

The means of securing and maintaining weathertightness will be subject to initial, annual and renewal surveys testing, to the satisfaction of the Administration.

REG 17 – MACHINERY SPACE OPENING

.mso .machinery space opening

Machinery Space opening shall be enclosed with steel casing with ample strength.

All access door opening at the casing, shall have minimum 600mm height of door sill at position 1, and 380m height at position 2.

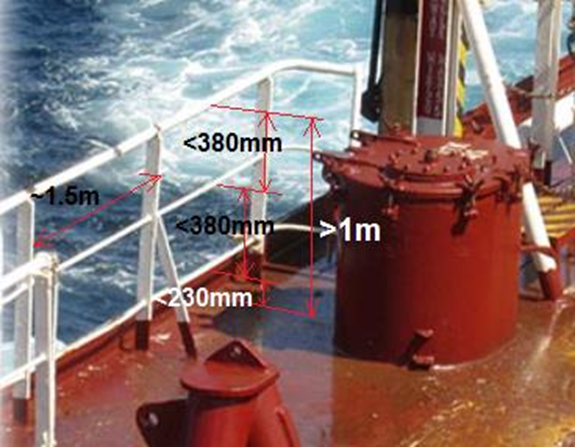

If machinery casing is directly exposed to weather, access door in way of the exposed casing bulkhead to have double weather tight door, outer door should have 600mm sill height, and inner door should have 230mm sill height.

Engine room and Emergency Generator room ventilators shall have coaming of height 4.5m if located in position1, or 2.3 meter in position 2. Reduced height could be considered if the ventilator come with weathertight closing arrangement and approved by the Administration.

REG 18 – MISCELLANEOUS OPENINGS IN FREEBOARD AND SUPERSTRUCTURE DECKS

All opening on freeboard deck and superstructure decks shall be protected by an enclosed superstructure or

deckhouse for weathertightness.

Opening which is not protected, should be covered with closely spaced bolts.

Wherever access is provided weathertight door need to be used; and door sill height to be 600mm at position 1 and 380mm height at position 2.

REG 19 -VENTILATORS

.ventilators

Ventilators shall have coaming of steel, with height of 900mm at position 1 and 760mm in position 2.

Ventilators to be provided with weathertight closing appliances of steel.

Ventilator more than 900mm height, additional support to coaming to be provided.

When ventilators coaming height exceed 4.5m in position 1 or 2.3m height in position 2, weathertight closing arrangement need not be provided unless specifically required by administrator.

REG 20 – AIR PIPES

.air pipes

Ballast and other tanks air pipes, need to be of substantial steel construction. The height to the point where water may access, shall be 760mm from freeboard deck, or 450mm from superstructure deck.

Air pipe need to be fitted with automatic closing devices, Pressure vacuum valves may be accepted on tanker.

REG 21 – CARGO PORTS AND OTHER SIMILAR OPENINGS

Cargo ports in the sides of ships below freeboard deck shall have doors with watertightness and structural strength similar as shell plating.

The lower edge of the door shall be 230mm above upper edge of upper most load line.

The door and their securing need to comply with requirement from recognized organization and the Administration.

REG 22 – SCUPPER, DISCHARGE, SPURLING PIPE & CABLE LOCKER

Scupper and discharge led through hull shall be fitted with efficient and accessible means to prevent water from passing inboard.

Sanitary and discharges led overboard in engine room, a locally operated positive closing valve at shell together with non-return valve need to be provided.

Spurling pipe and cable locker (chain locker) shall be watertight up to deck exposed to weather. Spurling pipes through which anchor chain are led, shall be closing arrangement to minimize water ingress

REG 23 – SIDE SCUTTLES, WINDOW AND SKYLIGHTS

Side scuttles are round or oval in shape, with glass opening area less than 0.16m2.

Windows are rectangular, round or oval in shape, with glass opening exceeding 0.16m2.

Side scuttles with deadlights to be fitted in spaces below freeboard deck.

when side scuttles to be fitted below the freeboard deck, it shall fit 500mm above summer load line.

Side scuttles, windows and skylights to be approved by the Administrator. Skylights shall be protected from

mechanical damage, and storm cover.

REG 24 – FREEING PORTS

Where bulwarks on the weather exposed freeboard or superstructure deck form wells, freeing port to be fitted for water drainage.

REG 25- PROTECTION OF CREW

.poc .protection of crew

Guard rail or bulwarks shall be fitted around all exposed decks. The height to be minimum 1 meter from deck.

Guard rail shall have at least 3 tiers. Lowest tier, less than 230mm from deck, while others to be less than 380mm apart. Stanchions to be fitted at about 1.5 meter apart. Every 3rd stanchion to be supported by bracket.

REG 26 & 27 – TYPES OF SHIPS & CONDITIONS OF ASSIGNMENT

Type “A” ship is ship designed to carry only liquid cargoes in bulk, and has high integrity of the exposed deck with small access opening to cargo spaces

Type “B” ship is ship do not come under Type “A”.

Type “A” ship shall have additional safe and permanent access between superstructure, poop, deck houses, wherever fitted. All exposed hatchways shall be watertight, Additional area of freeing port or half the length of weather deck need to be provided with guard rail.

Type “B” ship shall have increased freeboard, and more stringent consideration on flooding.

REG 40 – MINIMUM FREEBOARD

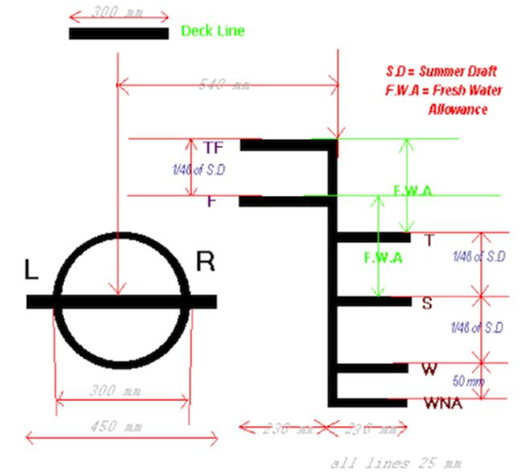

SUMMER FREEBOARD – Minimum summer freeboard shall be the freeboard found in table stated in Regulation 28.

TROPICAL FREEBOARD – Minimum freeboard obtained by deduction from summer freeboard of 1/4

of the summer draught.

WINTER FREEBOARD – Minimum freeboard obtained by additional to summer freeboard of 1/48 of the summer draught.

WINTER NORTH ATLANTIC FREEBOARD – Minimum freeboard obtained by “Winter Freeboard +

50mm” for ship <100m length, or same as winter freeboard for ship >100m length

FRESH WATER FREEBOARD – Minimum freeboard obtained by deduction of 1/48 of summer draught.

Annex III: Certificates

1. Certificate 1 International Load Line Certificate, 1966

Name, IMO, Registry, Length,

Freeboard assigned value, Type of ship, fresh water allowance

date of issue, place of issue,

2. Certificate 2 International Load Line Exemption Certificate

Name, IMO, Registry, Length,

Freeboard assigned value, Type of ship

fresh water allowance

date of issue, place of issue,

The voyage for which exemption is granted,

Condition for exemption

Annex IV: Verification and Compliance

Regulation 53:

Contracting Governments shall use the guidelines of the Code for Implementation to implement their obligations and responsibilities.

Regulation 54: Verification of compliance

(1) Every Contracting Government shall conduct periodic audits according to audit standard to verify compliance and implementation of the present Convention.

(2) The Secretary-General of the Organization shall have responsibility for the Audit Scheme, based on the guidelines.

(3) Every Contracting Government is responsible to provide audit facility and implement a programme of actions to address the findings, based on the guidelines.

(4) Audit of all Contracting Governments shall be:

(a) based on an overall schedule developed by the Secretary-General of the Organization, taking into account the guidelines developed by the Organization and

(b) conducted at periodic intervals, taking into account the guidelines developed by the organization.