Uncategorized

What are the important clearances/inspection to be carried out on a pressure-jet type burner?

1 min read

0 comments

Engr. Shafiul Bari

Shafiul Bari is a seasoned Marine Engineer with extensive experience in ship design, maintenance, and marine propulsion systems. With a deep technical knowledge of ship engineering and a passion for advancing maritime technology, Shafiul shares practical insights and expert advice to help marine professionals and enthusiasts better understand the complexities of ship systems. Through his website, he aims to bridge the gap between technical theory and real-world application, fostering a community of informed and skilled maritime engineers.

When not immersed in ship engines and technical manuals, Shafiul enjoys exploring the latest innovations in marine technology and mentoring aspiring marine engineers.

View Author Profile →During overhaul,

- The nozzle atomising holes should be inspected for signs of enlargement which can lead to improper fuel atomisation and bad combustion. Presence of cat fines in fuels will accelerate the wear of the nozzle holes.

- The swirler plate should be inspected for erosion corrosion. The swirler plate converts pressure energy to velocity and increases the speed of the oil flow to give the required atomisation, turbulence & penetration

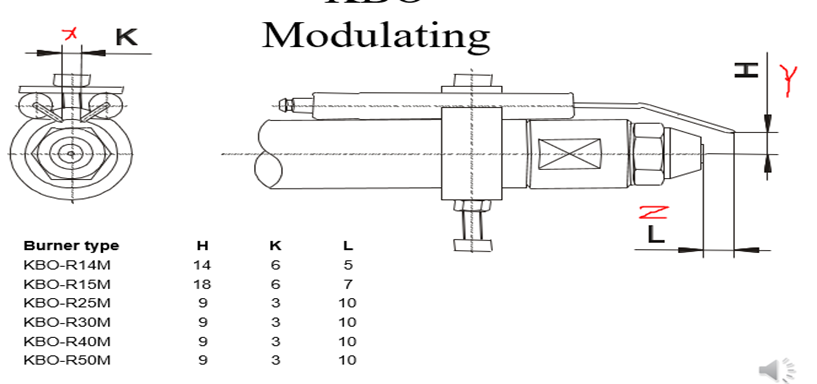

- The ignition electrodes’ clearances are critical for flame establishment during start-up and should be set as manufacturers’ recommendation.

4. The ignition electrodes’ tips should not be worn, carbonised or pitted.

5. The ceramic isolator body in the ignition electrodes should not be cracked or broken to prevent current leakage

6. The air swirler vanes should not be dirty/carbonised

7. Photocell checked for cleanliness

8. Filters in pump and burner checked for cleanliness

Share this article

Leave a Comment

Comments (0)

No comments yet. Be the first to share your thoughts!