Uncategorized

The Marine Growth Prevention System (MGPS)

2 min read

0 comments

Engr. Shafiul Bari

Shafiul Bari is a seasoned Marine Engineer with extensive experience in ship design, maintenance, and marine propulsion systems. With a deep technical knowledge of ship engineering and a passion for advancing maritime technology, Shafiul shares practical insights and expert advice to help marine professionals and enthusiasts better understand the complexities of ship systems. Through his website, he aims to bridge the gap between technical theory and real-world application, fostering a community of informed and skilled maritime engineers.

When not immersed in ship engines and technical manuals, Shafiul enjoys exploring the latest innovations in marine technology and mentoring aspiring marine engineers.

View Author Profile →.mgps

The Marine Growth Prevention System (MGPS) has been developed for ships with the sole purpose of tackling marine organism growth, preventing it from depositing on the ship’s interior piping systems, which are continuously supplied with sea water.

The anode in the MGPS system generates ions that spread in the seawater system, producing an antifouling and anti-corrosive layer over the internal sides of sea pipes, heat exchanger (i.e. coolers and condensers), valves in seawater system, refrigeration systems, AC units etc.

The three types of alloys used for anodes are:

- Copper Alloyed Anodes: This is the most used type to prevent marine fouling in piping, strainers, heat exchangers, pumps etc.

- Aluminium Alloyed Anodes: This type is used in conjunction with copper alloy anodes to prevent corrosion throughout the ferrous piping system.

- Ferrous Alloyed Anodes: They are used in conjunction with copper alloy anodes to prevent corrosion throughout Cu/Ni pipework.

An MGPS system can be installed on the ship in following ways:

- Anodes Mounted on Sea Chest: They are commonly installed in new buildings and have a working life such that they can run till the next drydocking.

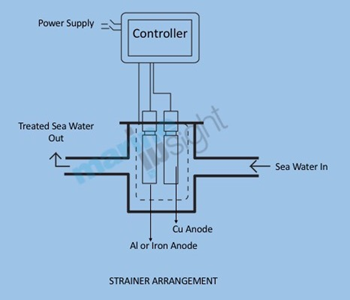

- Anodes Mounted in strainers in the seawater pipeline: They have an advantage of replacing the anodes without affecting the seawater supply to ship’s system.

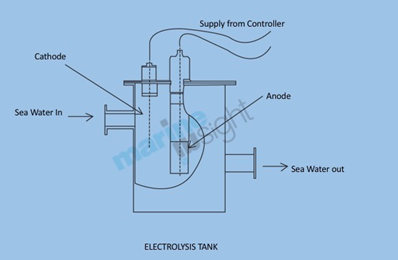

- Treatment tank setup with a spray nozzle in sea chest: In this system, a separate electrolysis tank with anodes is installed which sprays the ion through the nozzle in the sea chest. This system is installed on ships where sea chest or strainer mounting is not possible.

Share this article

Leave a Comment

Comments (0)

No comments yet. Be the first to share your thoughts!