Uncategorized

Removal of broken tie bolts

1 min read

0 comments

Engr. Shafiul Bari

Shafiul Bari is a seasoned Marine Engineer with extensive experience in ship design, maintenance, and marine propulsion systems. With a deep technical knowledge of ship engineering and a passion for advancing maritime technology, Shafiul shares practical insights and expert advice to help marine professionals and enthusiasts better understand the complexities of ship systems. Through his website, he aims to bridge the gap between technical theory and real-world application, fostering a community of informed and skilled maritime engineers.

When not immersed in ship engines and technical manuals, Shafiul enjoys exploring the latest innovations in marine technology and mentoring aspiring marine engineers.

View Author Profile →.removal broken tie rod .btr .broken tie

Safety precaution:

- Permission must be granted to immobilize the engine

- Propeller clearance to be obtained

- Block start air mechanism and shut start air. main valve

- Turning gear engaged & indicator cock must be opened

- Stop L.O pumps and shut all V/V’s

- Crankcase should be treated as enclose space entry permit to work combined with a risk assignment should be done.

Procedure

- If breakage does occur, engine can be operated with reduced load for a limited period

- Position of fracture will dictate how broken pieces are removed.

- If bolt broken at mid length, lift out the top half, remove the bottom nut

- Feed a loop of braided wire cable (about 7mm diameter) down the tie bolt tube

- When it emerges at bottom a supporting piece can be fitted to the wire

- This enable broken tie bolt to be withdrawn.

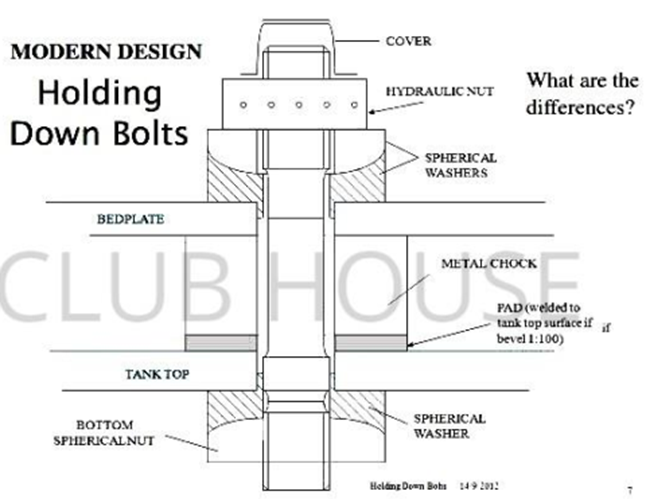

Holding down bolt

.holding down bolt .hdb

Share this article

Leave a Comment

Comments (0)

No comments yet. Be the first to share your thoughts!