Uncategorized

Refrigeration system:

2 min read

0 comments

Engr. Shafiul Bari

Shafiul Bari is a seasoned Marine Engineer with extensive experience in ship design, maintenance, and marine propulsion systems. With a deep technical knowledge of ship engineering and a passion for advancing maritime technology, Shafiul shares practical insights and expert advice to help marine professionals and enthusiasts better understand the complexities of ship systems. Through his website, he aims to bridge the gap between technical theory and real-world application, fostering a community of informed and skilled maritime engineers.

When not immersed in ship engines and technical manuals, Shafiul enjoys exploring the latest innovations in marine technology and mentoring aspiring marine engineers.

View Author Profile →Article link:

Sketch:

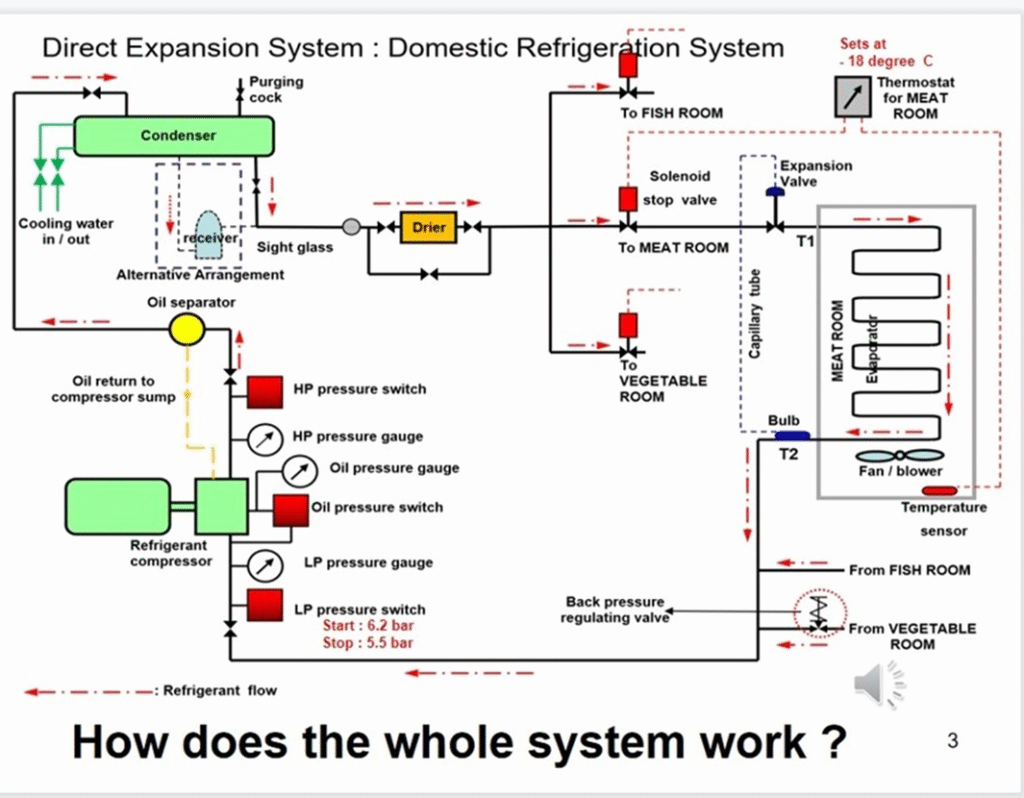

Direct expansion system:

.refrigeration system

→ evaporator coil situated inside the space to be refrigerated.

→ no duct and piping required

- The evaporator coil extracts the heat from the air inside.

- The compressor draws low pressure refrigerant vapour and delivers the high pressure refrigerant vapour through an oil separator to the condenser.

- The condenser liquefies the refrigerant.

- The liquid refrigerant from the condenser passes through the filter dryer, solenoid valve and thermostatic expansion valve to the evaporator.

Checks

Before starting the refrigeration plant,

- Check the oil level in the crank case of the compressor.

- Insufficient oil wears down the components.

- In extreme cases, it may lead to seizure of the compressor.

- Check whether the cooling water inlet and outlet valves to the condenser are open.

- Insufficient flow of cooling water results in improper condensation which in turn increases the compressor discharge side pressure.

- Open the compressor outlet valve, condenser inlet valve, receiver outlet valve, filter drier inlet valve and outlet valves.

- Check whether power supply is available to the compressor motor.

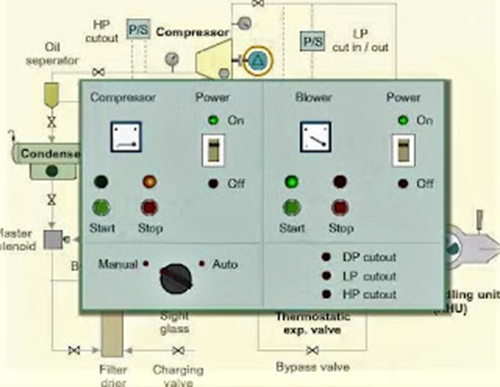

- Ensure the compressor is in manual mode.

During start

- Open the compressor inlet valve by half a turn and start the compressor.

- Open the compressor inlet valve slowly to fully open position.

- Change the operation of the compressor to automatic mode.

- Check the amperage of the compressor.

During operation:

- Check the compressor suction, discharge, and oil pressure.

- Inspect the compressor unit and check for any abnormality and vibration.

- Check the compressor oil level and check whether the oil returns from the oil separator to the crankcase

During auto Stopping:

- As the temperature reaches the set value, the thermostatic switch will cut off the compressor.

- The blower will continue to run.

- When the air temperature increases, the compressor will cut in.

To shut down for longer duration:

- To shut down for prolonged period, close the condenser liquid receiver outlet valve.

- The liquid refrigerant is collected inside the condenser receiver and the compressor stops due to low pressure.

- Shut the refrigerant line valves.

- Shut the condenser cooling water inlet and outlet valves.

- Switch off the power supply.

| AIR CONDITIONING SPECIFICATION | |

| SPECIFICATION | AIR CONDITIONING PLANT |

| Refrigerant | R-404 A |

| Cooling method | direct expansion system |

| Heating method | steam coil |

| Humidification | steam spray |

| Compressor | four cylinder, reciprocating |

| Condenser | horizontal shell & tube type |

| Main power source | 440 v AC, 60 Hz, 3 phase |

| Control circuit power source | 220 v AC, 60 HZ, 3PHASE |

Share this article

Leave a Comment

Comments (0)

No comments yet. Be the first to share your thoughts!