Uncategorized

Alternate Marine Power (AMP) or Cold Ironing

1 min read

0 comments

Engr. Shafiul Bari

Shafiul Bari is a seasoned Marine Engineer with extensive experience in ship design, maintenance, and marine propulsion systems. With a deep technical knowledge of ship engineering and a passion for advancing maritime technology, Shafiul shares practical insights and expert advice to help marine professionals and enthusiasts better understand the complexities of ship systems. Through his website, he aims to bridge the gap between technical theory and real-world application, fostering a community of informed and skilled maritime engineers.

When not immersed in ship engines and technical manuals, Shafiul enjoys exploring the latest innovations in marine technology and mentoring aspiring marine engineers.

View Author Profile →.cold ironing

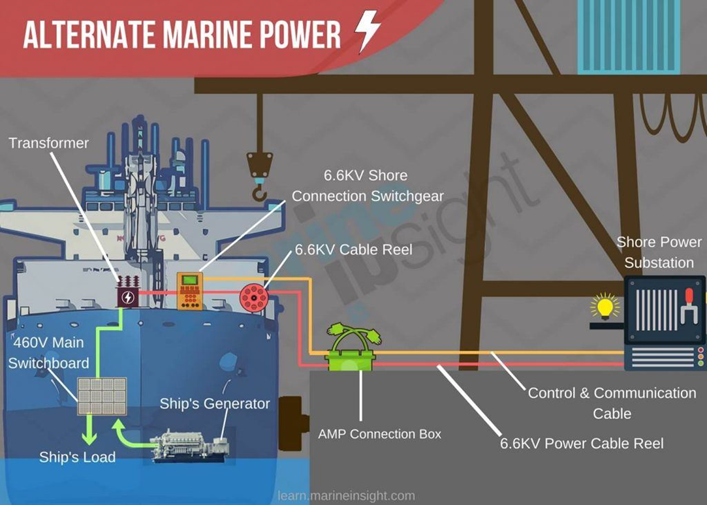

Alternate Maritime Power or AMP is an anti-pollution measure which helps in reducing air pollution generated from diesel generators by using shore electric power as a substitute.

AMP is used when the ship is stay at port, required to stop idling the engines (low load operation) and transfer the power source to a land base. This allows the ship to switch-off its generators. It helps in significant reduction in noise and air pollution.

- AMP done with the help of supply cables that are plugged into an electricity supply board in the port on one end and to the ship’s power supply board on the other. The process is called cold ironing.

- At present, there are four different variations in the AMP that is provided from the port to a ship.

- 11000 Volts of AC (Alternate Current)

- 6600 Volts of AC

- 660 Volts of AC

- 440 Volts of AC

The AMP system comprises major components such as – Cable Reel, Reel Control Centre & Pendant, Amp Connection Box, 6600v Shore Panel, Transformer, Main Switch Board, Amp Control Panel.

Share this article

Leave a Comment

Comments (0)

No comments yet. Be the first to share your thoughts!